Product Center Product Center

-

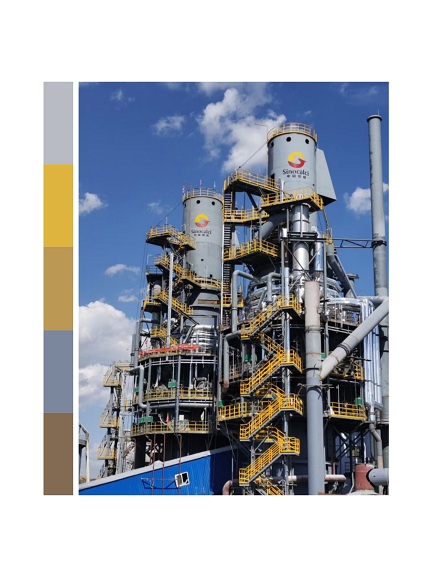

Annular shaft kiln

After years of unremitting efforts, Sinocalci annular shaft kiln technology has entered the third generation. The main characteristics of the third generation annular shaft kiln technology are the combination of perfect theoretical research and engineering standardization practice, the successful development of a number of innovative technologies, and comprehensively improve the energy conservation and environmental protection level and construction quality of the kiln. The sub projects of the third generation technology mainly include:

1. The introduction of flameless combustion technology in annular shaft kiln is a major scientific and technological innovation in the calcination industry. By redesigning the high-efficiency injection system, combustion chamber structure, flue gas external circulation and installing gas heat exchanger, the flameless combustion engineering platform was built, and the combustion environment with low oxygen and high temperature was constructed, and the flameless combustion technology was successfully realized in the kiln. The energy saving of the annular shaft kiln using this technology is about 10% higher than that of the ordinary technology. Meanwhile, the environmental protection performance is greatly improved due to avoiding the temperature range of producing thermal NOx.

2. Development and industrial application of pulverized coal combustion system in annular shaft kiln. The main body of the system includes quantitative pulverized coal distributor, conveying pipeline, pulverized coal burner and auxiliary control system. The pulverized coal burner of annular shaft kiln can be divided into independent type and combined type, which can be calcined completely with pulverized coal or in any proportion with gas. The project expands the fuel application scope of annular shaft kiln, and can calcine high-quality lime by using low calorific value lignite and other inferior energy, so as to further improve energy utilization efficiency.

3. The integrated R & D and application of noise reduction technology learn from the mature technology at home and abroad, and greatly reduce the noise level of kiln top with unique low-cost and high-efficiency means. At the same time, the blower room is fully enclosed to further reduce the noise level around the annular shaft kiln and form an environment-friendly operating environment.

-

Address: No. 185, Yanhu Road, Jiangning Economic and Technological Development Zone, Nanjing

Phone: 025-58071620

Phone: 137 7066 0602

Fax: 025-58071640

Email: http://mail.sinocalci.com/

-

Company Overview Company Profile Company Culture Qualification Honor

Performance Presentation Calcination field Industrial incineration field Solid waste recycling field Managed Operations